Additive manufacturing, also known as 3D printing, is a manufacturing methodology where the piece or product is manufactured layer by layer. To understand what makes this technology interesting we can use computers as a simile. How does a word processor improve over a typewriter? On the one hand, with the processor you can correct and rewrite if you make a mistake, but it also allows you to work faster, and only when you are satisfied with what you have written you send it to be printed. The computer, then, made it possible to make processes more flexible and gave us more creative freedom. Moved to additive manufacturing, the samehappens.

Everything starts with a computer drawing of what you want to manufacture, and it is sent to a machine that is capable of depositing material to reconstruct the piece in overlapping layers. This is precisely where the concept of additive manufacturing is born, as opposed to the traditional mechanized manufacturing system, which consists of removing material from a block of a certain size, in order to manufacture a piece of smaller size.

So, with traditional manufacturing, material is lost, and here we have a key element of additive manufacturing, which is more sustainable in the sense that it only uses the material necessary to make the part we are looking for. But if 3D printing is associated with a differentiating element, it is undoubtedly the degree of freedom it brings when manufacturing any item.

One technology, several possibilities

Although we refer to additive manufacturing in singular, it is not a single technology: this manufacturing process includes many technologies. Some to work with polymers, others with ceramics, with metals, even with biological materials or with composite materials that integrate different types of materials. If we think that in its beginnings, 3D printing was only used for the manufacturing of rapid prototypes, but today it is possible to manufacture high-quality final parts with a wide variety of materials. It seems, then, that additive manufacturing has reached its highest point. However, the reality is that each of the technologies associated with 3D printing is in a different state of development.

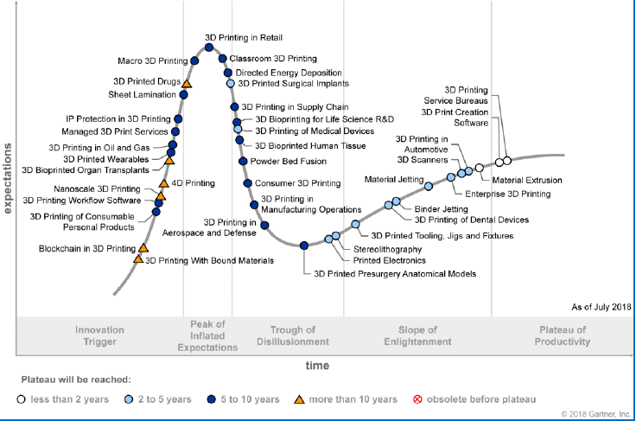

There is an interesting graph in which you can see the typical curve of expectations when a disruptive technology appears on the market: at the beginning it generates a lot of enthusiasm, everyone signs up to use it and thinks it will solve all possible challenges. However, as the available knowledge about the technology expands, obstacles appear, some of them impossible to solve, and interest declines. Finally a certain stability is achieved in which the meaning and realistic uses for this technology are found.

In this graph you can see exactly how each technology associated with additive manufacturing is at a specific stage of development: some are in their initial stages, others are already falling short of the expectations generated, while there are others that are on the way to entering the manufacturing dynamics to generate innovation.

A continuous focus on innovation

Since talking about 3D printing is usually associated with the innovation concept, it is interesting to stop and consider its meaning. One way to define innovation is by referring to all change, not just technological, knowledge-based, not just scientific, that generates value, not just economic. With such a statement it seems that we do not define anything, because the meaning of innovation is greatly expanded, but in reality it includes the three key words: change, knowledge and value. If all three are not present, there is no innovation. Therefore, it is a process in which novelties are introduced with which existing elements are modified in order to improve them or make them more efficient, but it is also makes it possible to implement completely new solutions that generate value.

INNOVATION IS ALL CHANGE, NOT JUST TECHNOLOGICAL, BASED ON KNOWLEDGE, NOT JUST SCIENTIFIC, THAT GENERATES VALUE, NOT JUST ECONOMIC

This new “something” that appears is a driving force to innovate, and throughout history we have seen it on multiple occasions. Vacuum cleaners, for example, went from being heavy, manual wooden and leather devices to the machines we know today: light, very powerful, without the need to be connected to electricity and even autonomous. And all this in a time span of 50 years: less than a human life.

This brings us to a new variable associated with innovation, which is time. Today, changes are happening faster and faster. Additive manufacturing, for example, is a very new technology, only around 30 years old, during which time it has become increasingly competitive. And this speed forces us to change the way we see and integrate innovation: it must be part of the day-to-day of organizations, not be one-off or associated with a fad. In fact, innovation does not even require creating something completely new: if we think of the steel that carries the body of a modern car, it is an innovation that did not exist 25 years ago, despite the fact that humans have been working with steel since the industrial revolution.

In this context, additive manufacturing appears as a new scene that breaks the traditional way of manufacturing and pushes us to the possibility of local production, in small series, with the ability to adapt a lot to the customer’s needs, etc. 3D printing, then, is a new opportunity to innovate. And ThinkIn 3D Mataró is a paradigmatic example of the need to join forces and have a joint vision: from TecnoCampus and the Mataró City Council with the decisive support of the Incyde Foundation, the accelerator is born, a piece of equipment that makes this new technology accessible to the entire production industry and which is a source of wealth, not only economic, but also aimed at generating employment with high added value. Because we surely know that by innovating on our own we may be faster, but if we innovate togetger, we will go further and we will all win as a society.

Tenim els ingredients necessaris per a la innovació, ens acompanyes?

This content has been produced based on José María Cabrera’s presentation entitled “Additive manufacturing and innovation: a new opportunity”, which he presented as part of Thinkin 3D opening in March 2023.