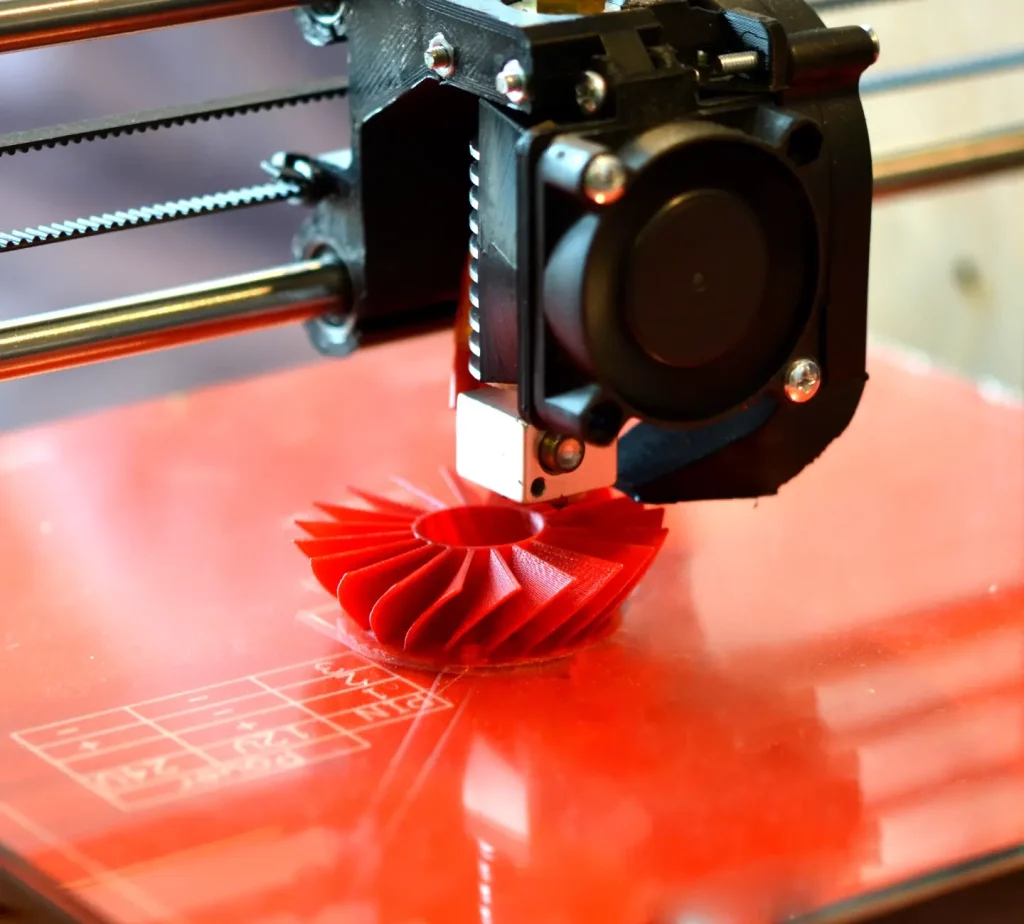

3D PRINTING TECHNOLOGY:

3D printing, also known as additive manufacturing, refers to a set of technologies that allow volumetric objects to be created from digital models. This technology takes on even more strategic importance in a global context of energy crisis, logistics and climate change. Benefits to the fabric of SMEs and micro-SMEs.

CUSTOMIZATION

Makes it possible to respond to the trends of adapting products to the needs of users, allowing total customization.

FLEXIBILITY

It allows the manufacture of the necessary quantity and with the material that is required to cope with the changes in design and demand.

ADDED VALUE

Additive manufacturing allows you to generate complex three-dimensional geometries that cannot be performed with other technologies. It also makes it possible to manufacture lightweight structures or the use of special materials.

KM0 MANUFACTURING

The possibility of producing short series of products with a high level of adaptation allows competing in quality, innovation and flexibility with local equipment, reducing logistics and environmental costs (reduction of the carbon footprint).

TIME TO MARKET

It makes it possible to streamline the process of product design and development, as well as its manufacture. This makes it a very interesting technology for sectors that continuously innovate in their products.

TRANSVERSALITY

It is a technology that can be applied in many sectors, either in the field of production or in the manufacture of prototypes or tools.

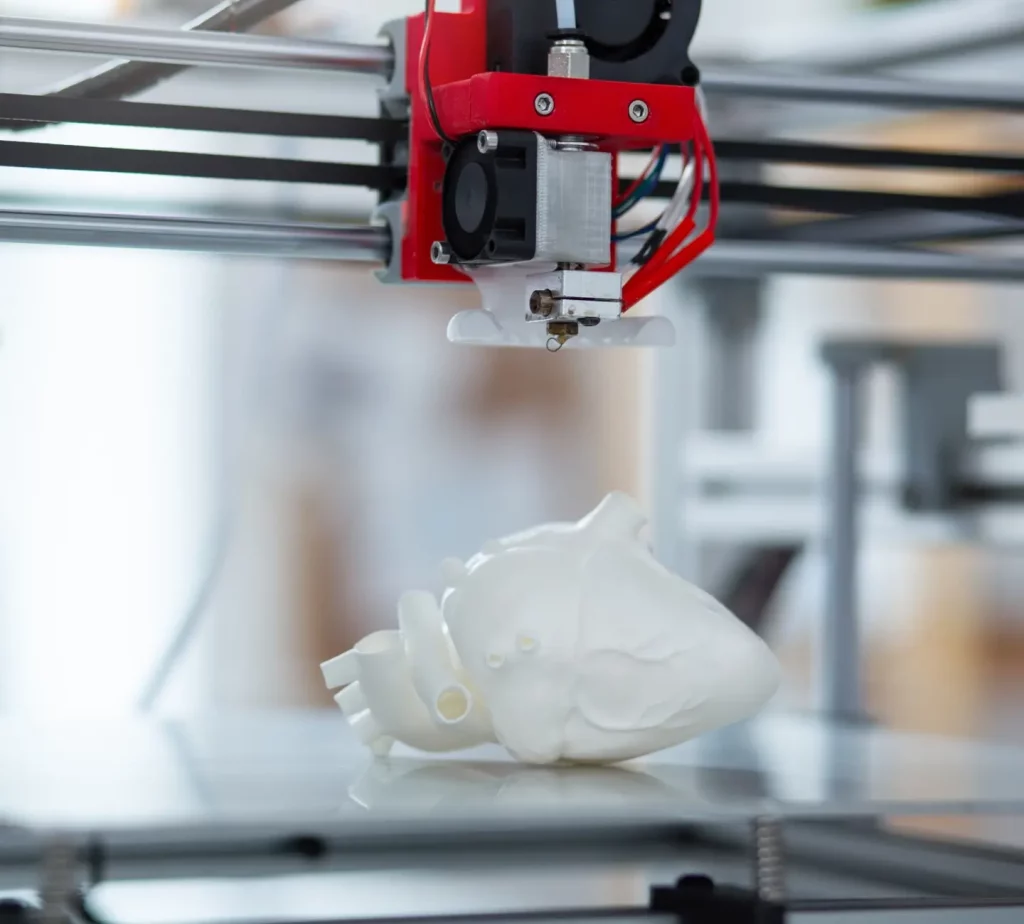

HEALTH

3D printing in the field of health has multiple applications: prostheses, dental implants, splints, medical devices, physiotherapy products,bioprinting of tissues, medical prostheses, prototypes and surgical and pre-surgical models and printing of biocompatible implants.

Additive manufacturing provides significant health advantages: it helps avoid possible postoperative surgeries, It improves the quality of the surgical process, allows the use of biocompatible materials as well as the manufacture of personalized prostheses.

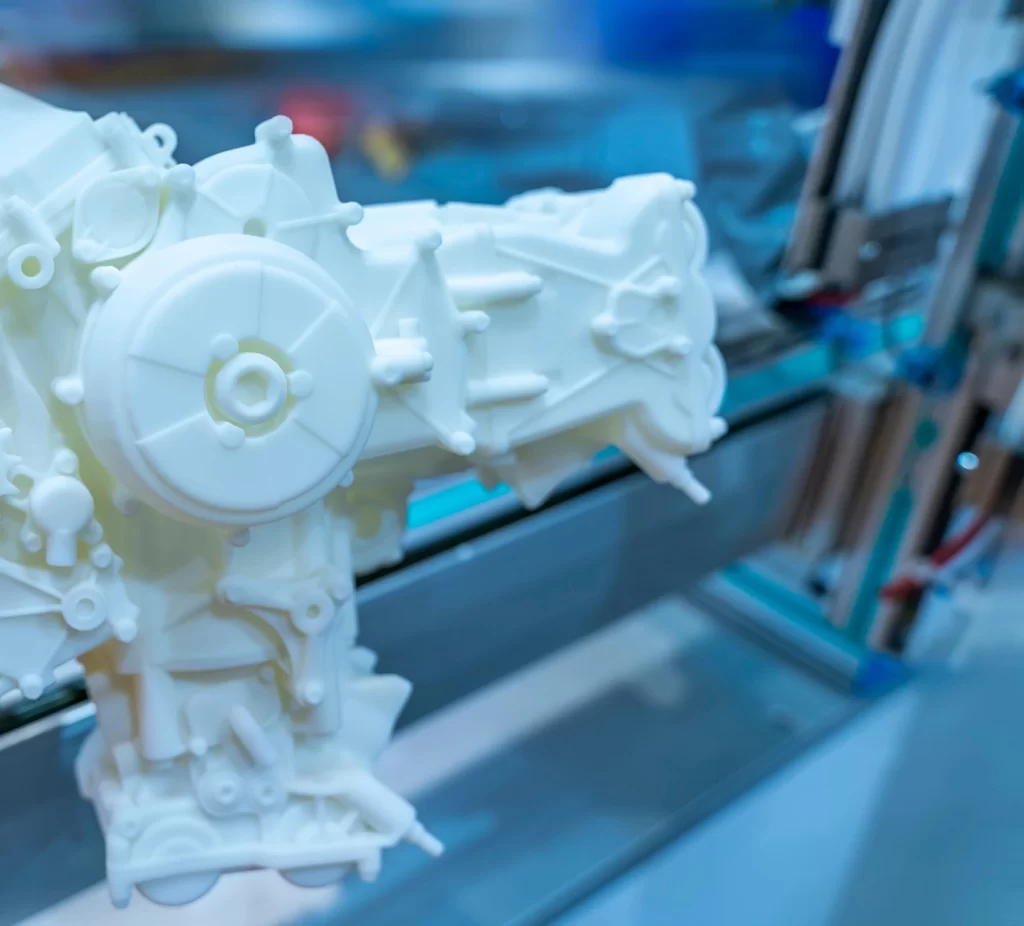

AUTOMOTIVE SECTOR

Additive manufacturing in the automotive sector provides speed and flexibility in production, reduces costs, allows customization of pieces and the manufacture of km 0, as well as the small-scale production of pieces for repairs or that are difficult to find because they are discontinued.

Some applications of 3D printing in this sector are the creation of prototypes, tooling and tools, the manufacture of entire chassis, brake and pneumatic control systems, etc.

CONSTRUCTION

The use of additive manufacturing in construction helps to create complex geometries that could not be done with other construction systems and to build structures faster, as well as a significant reduction in CO2 emissions compared to conventional processes and the recovery of residual materials with a circular economy logic.It is applied from concrete to prefabricated infrastructures, ceramic pieces of complex shapes or prefabricated houses.

FASHION AND TEXTILE

3D printing applied to fashion allows you to offer complex custom designs as well as the chance to customise the final product and adapt it completely to the morphology of each person. It also enhances complex custom designs in garments such as bags, glasses, technical footwear or accessories for dresses.

INDUSTRY

3D printing brings important advantages to the industry as it allows you to try new ideas quickly, helps to innovate continuously, it provides flexibility in manufacturing processes, allows customization and can reduce costs. All productive sectors can be included in this group.