APPLICATIONS OF 3D PRINTING

The applications of 3D printing have revolutionized the way we design and manufacture parts for a wide range of industries.

Discover applications of 3D printing and get inspired to boost your business:

Next, we explore specific applications that highlight the versatility and efficiency of this technology.

Discover how those applications of 3D printing is revolutionizing manufacturing sectors, from automotive to medicine, with real-world application examples that can help your business grow.

Sectors where it applies

AUTOMOTIVE

Additive manufacturing in the automotive sector provides speed and flexibility in production, reduces costs, allows for the customization of parts and the manufacture of km 0, as well as the small-scale production of parts for repairs or that are difficult to obtain because they are discontinued.

Some applications of 3D printing in this sector are the creation of prototypes, tooling and tools, the manufacture of entire chassis, brake and pneumatic control systems, etc.

CONSTRUCTION

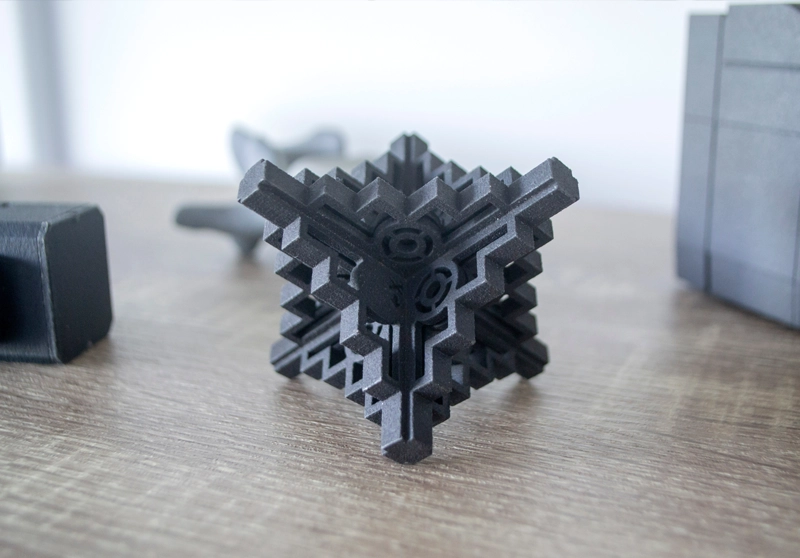

The use of additive manufacturing in construction helps to create complex geometries that could not be done with other construction systems and to erect structures faster, as well as a significant reduction in CO2 emissions compared to conventional processes and the valorization of residual materials with a circular economy logic. The applications of 3D printing in this area range from concrete to prefabricated infrastructures, ceramic pieces with complex shapes or prefabricated houses.

TEXTILE

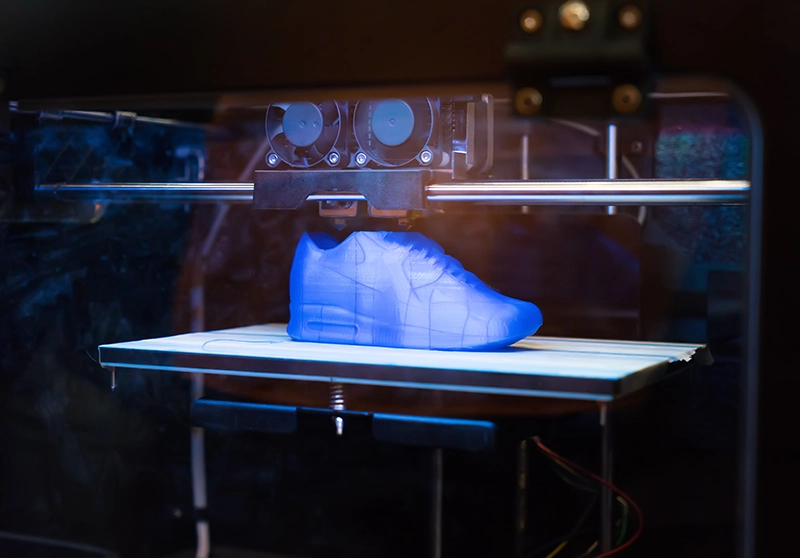

3D printing applied to fashion allows for complex custom designs as well as personalizing the final product and adapting it completely to the morphology of each person. Some applications of additive manufacturing in textiles are the production of bags, custom glasses, personalized technical footwear, accessories or dresses.

INDUSTRY

3D printing brings significant advantages to industry, as it allows new ideas to be tested quickly, helps to innovate continuously, provides flexibility in manufacturing processes, allows for customization and can reduce costs. All production sectors can be included in this group.

RAPID PROTOTYPING: REDUCES TIME AND COSTS

3D printing enables rapid prototyping, facilitating the creation of product iterations more quickly and cost-effectively. This application is especially useful in new product development, as it allows companies to experiment with various forms and functions before launching production.

END-USE PARTS: CUSTOMIZATION AND FUNCTIONALITY

3D printing also allows for the manufacture of finished garments that are commercially available. The wide variety of materials available, from plastics with different strengths to the use of colors, makes it possible to create functional components tailored to each specific need.

OBSOLETE SPARE PARTS

Thanks to reverse engineering, 3D printing allows for the reproduction of spare parts that are no longer manufactured. This is especially useful for sectors such as the automotive or aerospace industries, where older parts are difficult to find.

CUSTOM DESIGNS

With 3D printing, custom designs are more accessible than ever. This technology allows for the creation of complex and personalized geometries without the limitations of traditional manufacturing methods.

HIGH DEFINITION MODELS AND MOCKUPS

The ability of 3D printing to produce high-definition models and mock-ups is very useful for architects and designers. These representations allow them to visualize and test ideas before final manufacturing.

CUSTOM-MADE TOOLS AND SUPPORTS

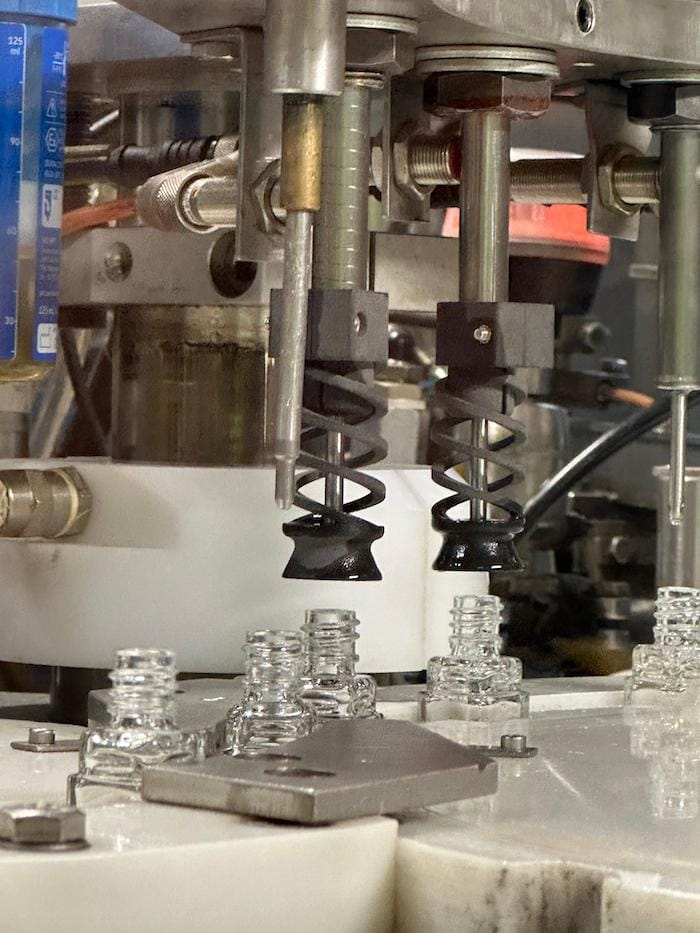

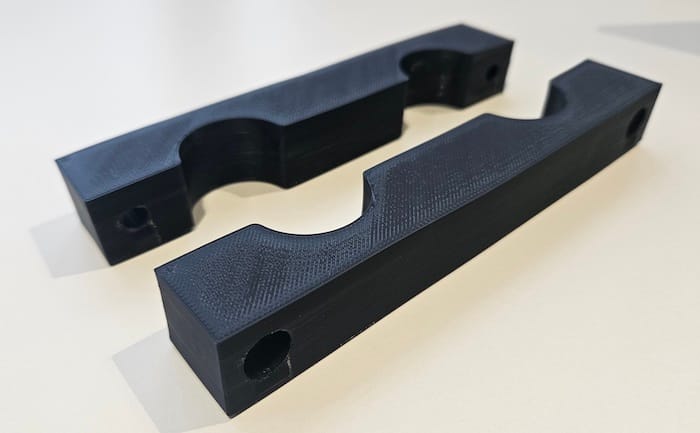

3D-printed tools and fixtures are essential for maintenance and production. They help position and hold components correctly in the manufacturing process.

GUIDES

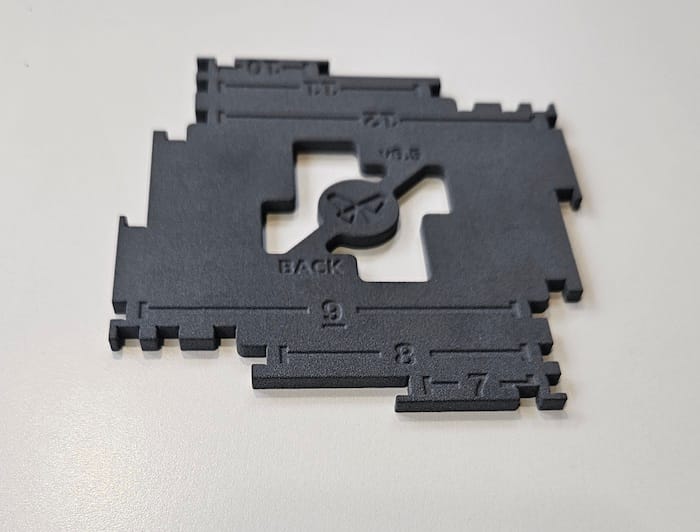

AND TEMPLATES

3D printing also facilitates the creation of guides and templates, ensuring precision in manufacturing. These tools are essential for the production line and product assembly.

CUSTOM MANIPULATION TOOLS

Customized handling tools, such as grippers or handles, can be specifically designed for particular tasks on the production line, improving productivity and safety.

TEMPORARY SUPPORT STRUCTURES

Temporary support structures are useful for holding components in position during assembly. These structures can be easily removed after the manufacturing process is complete.

MEASURING DEVICES

Finally, 3D printed calibration devices help ensure that manufactured parts meet exact specifications, guaranteeing the quality of the final product.

Explore how companies have effectively leveraged 3D printing applications successfully and boosted their businesses.